Biogas is produced by the anaerobic fermentation of biomass, for example, residues from the food industry, waste, sewage sludge or renewable raw materials. In fermenters, biogas is produced from the biomass in anaerobic fermentation. Depending on the origin of the biomass, the gas composition of the biogas varies. A typical gas composition is 60% CH4 (methane) and 40% CO2 (carbon dioxide). The gas is humid (saturated with water) and contains pollutants like H2S. Moisture and H2S are removed in the pre-cleaning.

In the fermenters and the pre-cleaning usually low-pressure blowers are used. Compressors are needed if the biogas is to be stored or treated, so that the methane content is greater than 96%. The biogas treatment can be done by different methods. Practically all require a process pressure of 6 to 15 bar, which are generated by compressors.

Examples of biogas/biomethane compressor applications:

- Preparation of biogas to biomethane

- Feed into the natural gas network

- Provision for vehicle refueling

- Biogas cycle compression in fermentation

- Biogas, biomethane and CO2 compression for storing excess electrical energy in the natural gas grid (power-to-gas)

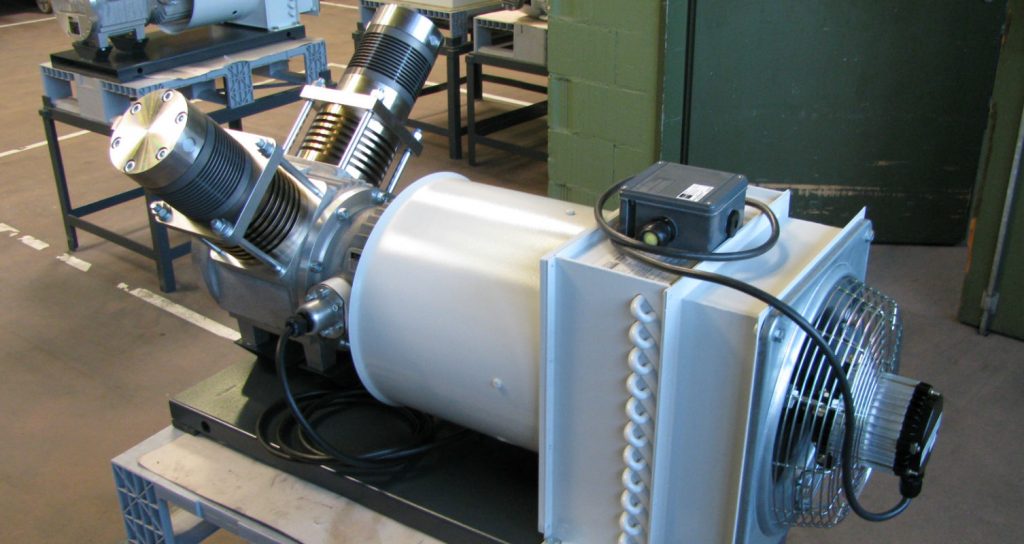

Thanks to their oil-free, dry-running and gas-tight design, HAUG piston compressors are ideal for many biogas and biomethane applications.

- no gas contamination by oil

- technically tight, in operation and at standstill

- flexible concerning variable suction and discharge pressure

Please download the HAUG company profile and specific compressor data sheets for more information.

Download the Haug Company Profile Brochure Here

Click Here to Learn More About Haug Compressors

You must be logged in to post a comment.